Each year in the U.S., an average of 38 workers lose their lives, and 2,700 more experience serious heat-related illnesses on the job, and those are just the reported cases. The reality is far worse, especially in industries where workers face extreme temperatures while wearing full-body PPE. Heat stress can escalate quickly, leaving workers vulnerable, supervisors unaware, and companies exposed to costly consequences.

Picture a construction crew working on a mid-July afternoon. Temperatures are soaring past 95°F, and workers are pushing through their shifts. One worker, feeling dizzy and overheated, doesn’t recognize the early signs of heat stress. By the time help arrives, the situation has already turned dangerous. This scenario happens far too often, and traditional safety guidelines aren’t enough to prevent it.

To combat these risks, many organizations rely on general heat stress thresholds like Wet Bulb Globe Temperature (WBGT) or OSHA recommendations. Unfortunately, these broad standards don’t reflect real-world conditions, like individual differences in fitness, hydration, and acclimatization, or the demands of high-intensity jobs. They create dangerous blind spots, leaving safety teams unable to intervene until it’s too late.

It’s time to rethink how we monitor and manage heat stress. By shifting to personalized safety thresholds based on real-time data, companies can prevent incidents more effectively and protect their most valuable resource: their people.

Why Traditional Heat Stress Guidelines Fall Short

Heat stress affects every worker differently. Yet, traditional safety standards rely on broad averages. While these guidelines may work in controlled settings, they fail to account for real-world conditions, where high-exertion tasks, extreme environments, and individual differences create unpredictable risks.

The key gaps in traditional guidelines include:

- Ignoring Individual Variability: Two workers in the same environment, doing the same job, can have very different physiological responses to heat. Factors like age, fitness level, hydration, and acclimatization all play a role. Standard thresholds treat everyone the same, which means some workers are left unprotected while others receive unnecessary work stoppages, reducing efficiency without improving safety.

- Overlooking PPE and Workload: Wearing full-body protective gear traps heat, making it harder for workers to regulate their body temperature. Add in physically demanding tasks, like lifting heavy materials, operating machinery, or working in confined spaces, and heat stress risks escalate far beyond what environmental data alone can predict. Without factoring in exertion levels, traditional guidelines give a false sense of security.

- Lack of Real-Time Monitoring: Heat stress isn’t static; it builds over time and affects workers differently throughout a shift. Static thresholds based on external conditions, like temperature or humidity, don’t reflect what’s actually happening inside a worker’s body. By the time symptoms appear, it may already be too late to prevent heat exhaustion or heatstroke.

The result? Workers push through symptoms they don’t recognize until it’s too late, and supervisors can’t always tell who needs immediate help. Unfortunately, while traditional heat stress guidelines provide a starting point, they leave too much to chance.

The reality is that heat stress is unpredictable and it affects every worker differently, depending on their body’s response and the demands of the job. To truly protect workers and reduce risks, companies need a more precise, real-time approach that adapts to each worker’s unique conditions.

Personalizing Safety Thresholds: A Better Approach

Relying on generic heat stress guidelines is like applying the same speed limit to every road, ignoring sharp turns, steep inclines, and changing conditions. Every worker reacts to heat differently, and job sites vary in ways that standard thresholds fail to capture. The only way to truly protect workers is through real-time physiological monitoring and personalized safety thresholds that reflect actual conditions, not broad estimates.

Traditional guidelines focus on environmental factors alone, such as temperature, humidity, and radiant heat. While these are important, they don’t account for individual differences in heat tolerance, fitness level, hydration, or acclimatization. However, by using real-time data, safety teams can make more precise decisions, prevent heat stress before it escalates, and intervene when workers need help—not when a generic standard says they should.

The Advantages of Personalized Heat Safety

1. Real-Time Alerts for Immediate Action

The human body doesn’t send a clear warning when it’s about to overheat, but technology can.

With continuous monitoring of heart rate, core body temperature, and exertion levels with wearable technology, workers and supervisors can receive immediate alerts when critical thresholds are exceeded. Instead of relying on workers to self-report symptoms, often when it’s already too late, real-time data triggers proactive interventions before heat stress becomes a medical emergency.

2. Smarter Decision-Making for Safety Leaders

Supervisors often have to make judgment calls about when to slow work down, when to rotate workers, and when to call for breaks. Without real-time data, these decisions rely on guesswork, leading to either missed warning signs or unnecessary stoppages that disrupt productivity without actually improving safety.

By tracking real-time worker strain, supervisors can:

- Fine-tune work/rest cycles based on actual conditions rather than following rigid schedules.

- Reduce false alarms, preventing unnecessary interruptions that slow down work.

- Identify at-risk workers early, allowing targeted interventions instead of treating the entire workforce the same.

With real-time insights, teams can respond before heat stress becomes an emergency, reducing downtime and improving overall workplace efficiency. However, bringing this level of precision to heat stress management requires advanced monitoring tools that track both physiological and environmental conditions.

How SlateSafety Makes Personalized Safety Possible

Preventing heat stress isn’t about guessing; it’s about knowing. SlateSafety’s solutions bring this proactive, personalized approach to life by providing continuous monitoring, instant alerts, and actionable insights that adapt to real-world conditions.

Here’s how:

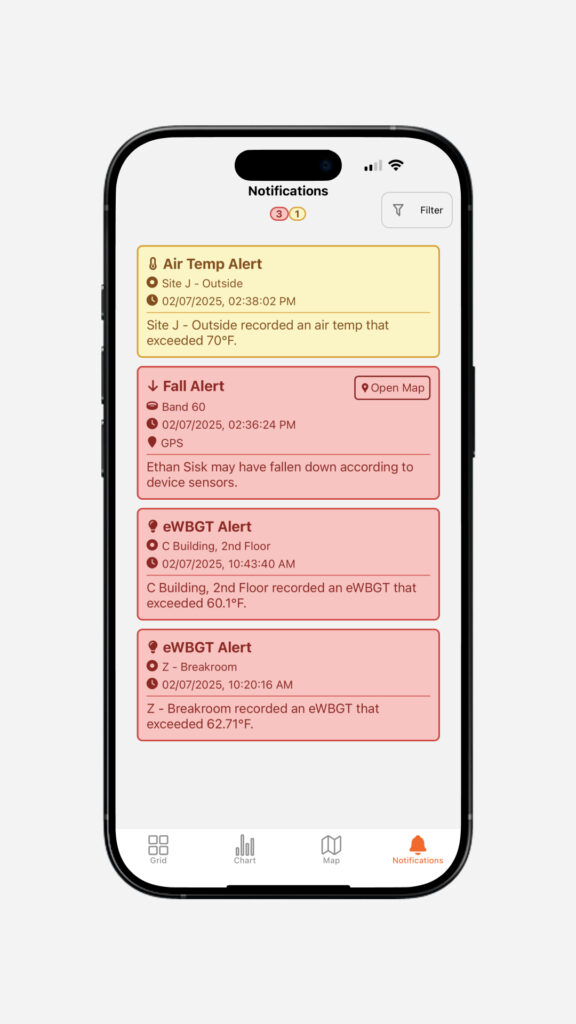

- BAND V2 Wearable Device: Tracks vital signs and alerts workers and supervisors when critical limits are reached, allowing immediate action.

- BEACON V2 Environmental Monitor: Provides key environmental data, such as temperature, humidity, heat index, and eWBGT (enhanced Wet Bulb Globe Temperature), offering a more accurate and dynamic alternative to traditional WBGT devices. Working alongside the BAND V2, it delivers a comprehensive, real-time view of heat stress risk, enabling more precise decision-making and proactive interventions.

- Edge-Based Cloud Architecture: Ensures secure data processing and storage with seamless integration into your existing systems.

- User-Friendly Dashboards: Real-time insights and analytics help safety teams monitor conditions and adjust safety protocols quickly.

These tools take the guesswork out of managing heat stress. Personalized thresholds powered by real-time monitoring can transform how your organization approaches safety.

Are you ready to move beyond outdated standards and adopt a personalized approach? Explore how SlateSafety’s BAND V2 and BEACON V2 can help you protect your team and build a stronger, safer workforce.